Production

Putting the client at the heart of the production process

Gallo Tessile, to offer its clients the best possible combination of value for money and service, handles most of its product processing stages in-house.

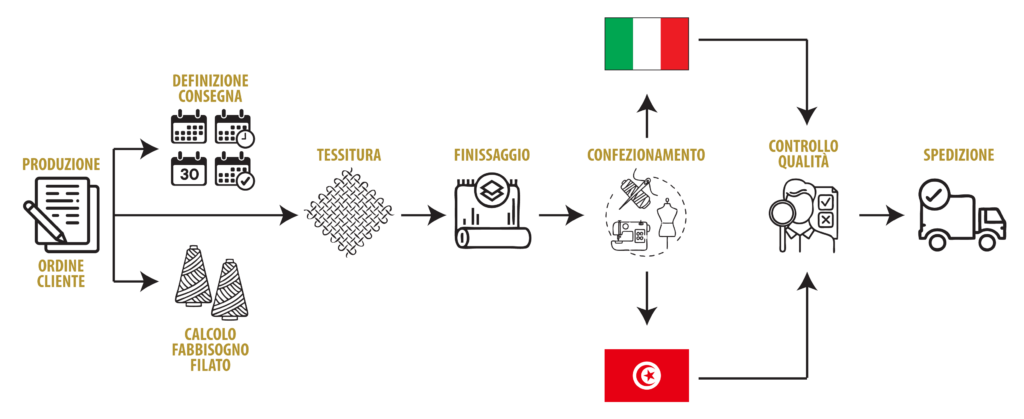

Productive Cycle

We operate a vertical production cycle, from the purchasing of the yarn to the delivery of the sample, which means that we do not have to rely on external facilities, other than for fabric finishing. This helps us keep processing times down as well as ensure that agreed delivery deadlines are met.

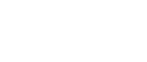

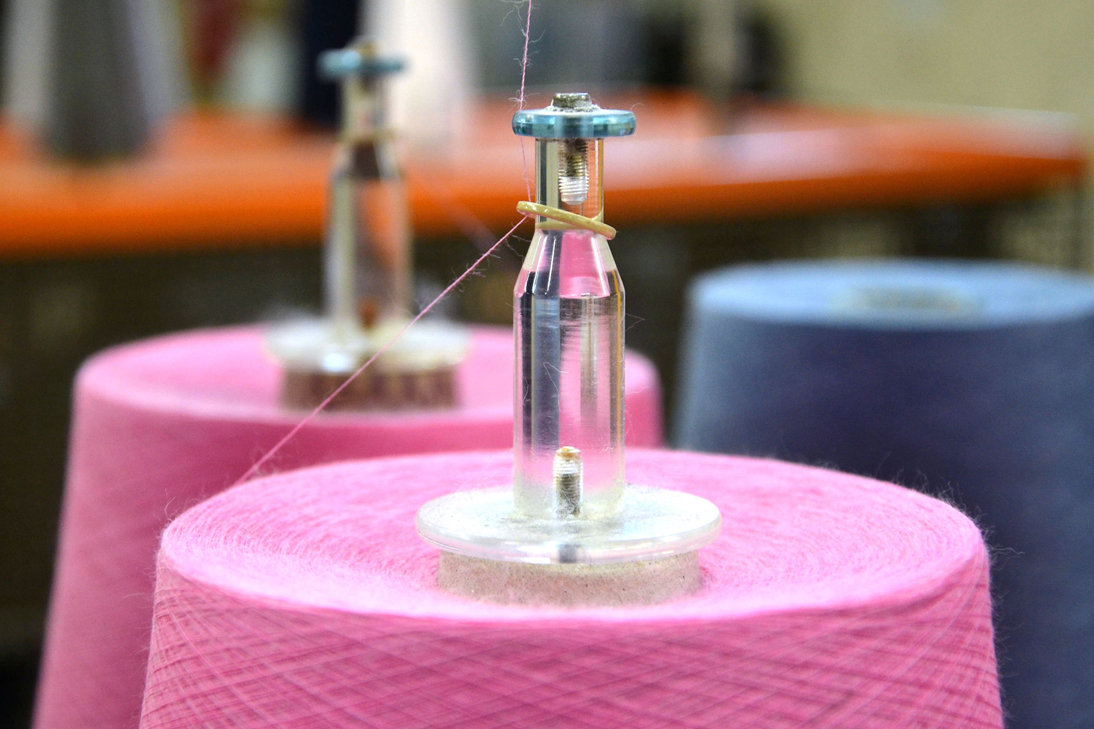

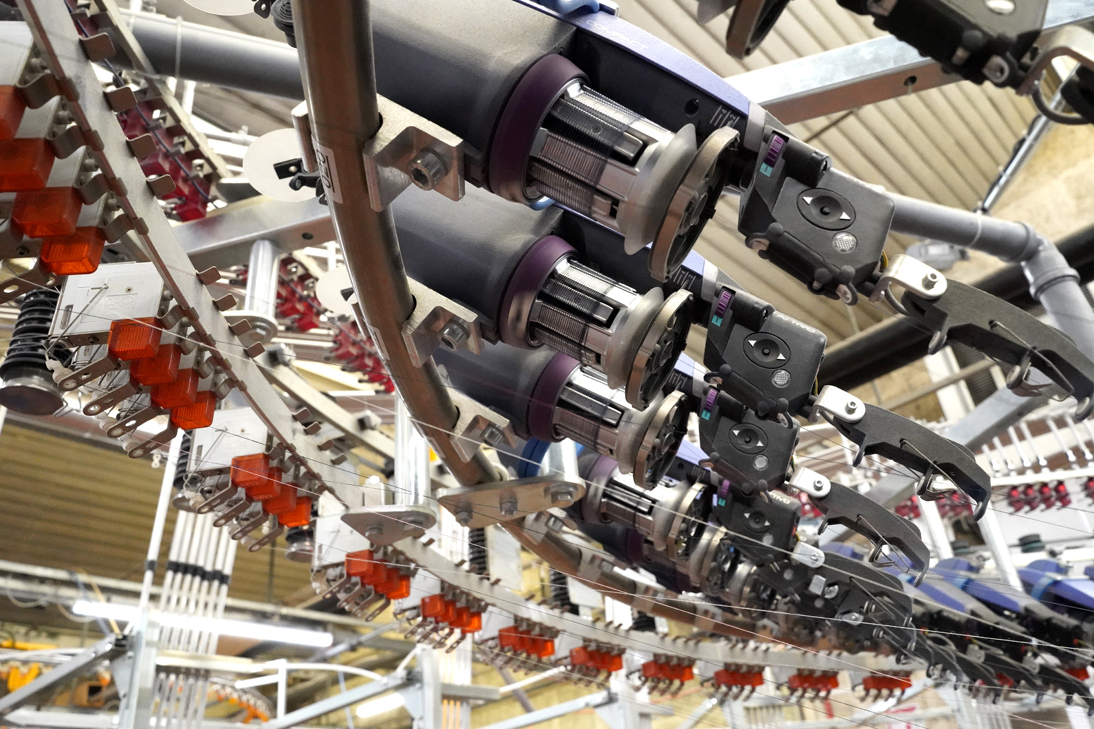

Knitting Department

It consists of the electronic circular machinery department of various gauges and the Stoll flat knitting machines department for the accessory parts to the garment (collars, edges, flounces, cuffs, etc.).

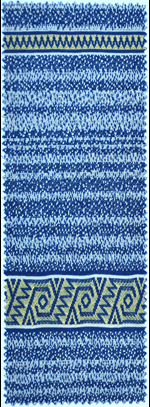

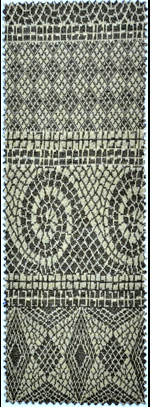

One standout is the archive of garments produced over the years that gathers together almost everything that can be created on these machines.

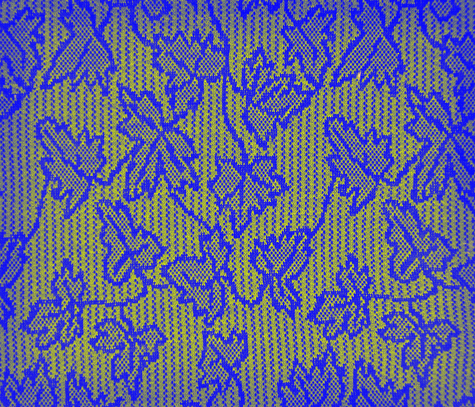

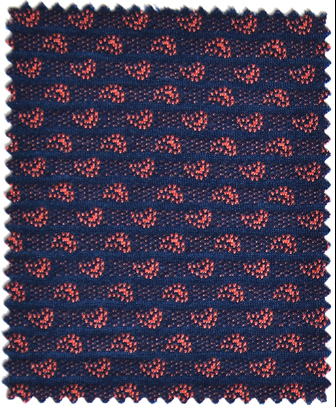

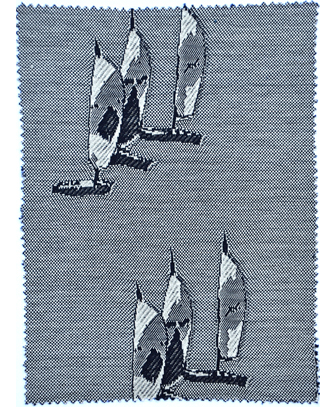

Examples of jacquard fabrics that are part of our archive that contains over a thousand designs

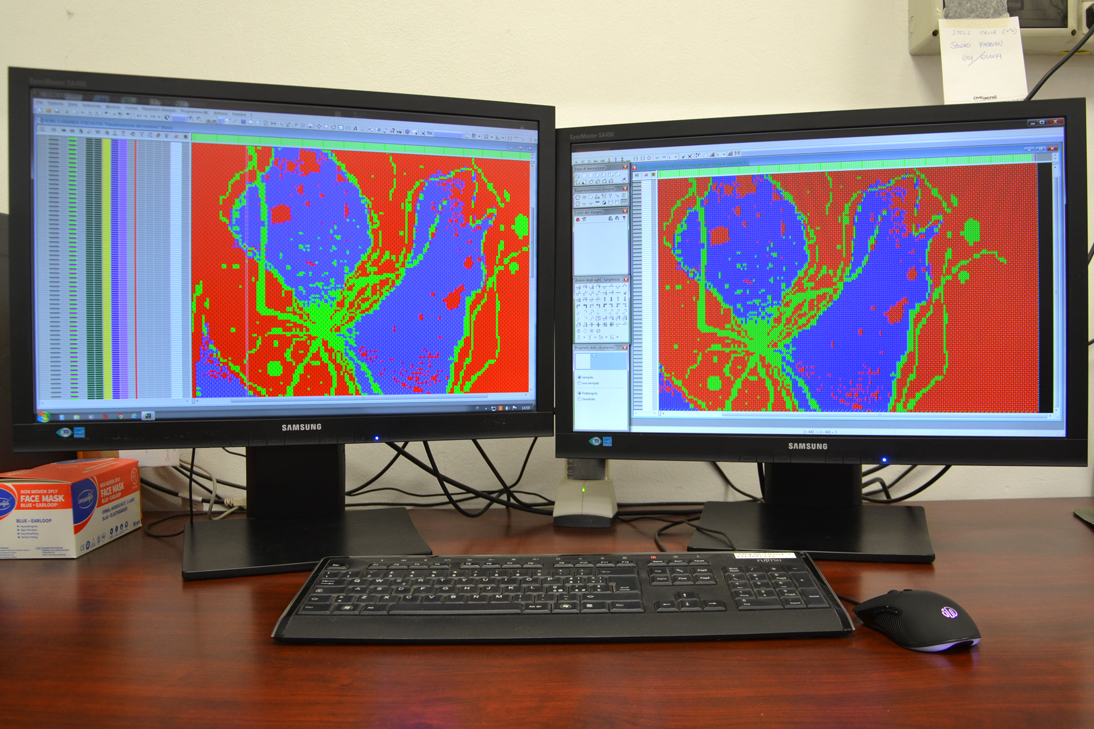

Modelling and Prototyping Office

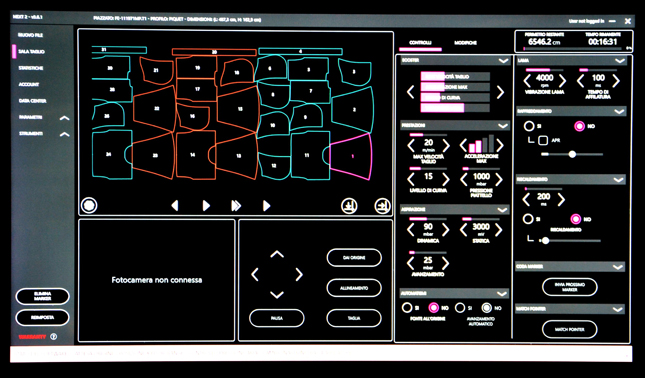

Gallo Tessile makes use of the most modern computer CAD systems able to develop any type of modelling either for men, women and children as well as customised size developments to meet any specific requests from designers and customers.

Production Sites

In 2008, Gallo Tessile established Gallotex s.a., its own production site in Jamel, Tunisia. The aim was to increase our market competitiveness in terms of quality-price ratio and mark up, and therefore better meet the demands of our clients.

The fabrics processed in this company are produced in Italy and the majority at the Mortara site.

From purchasing the yarn to delivering the finished product